How It Works

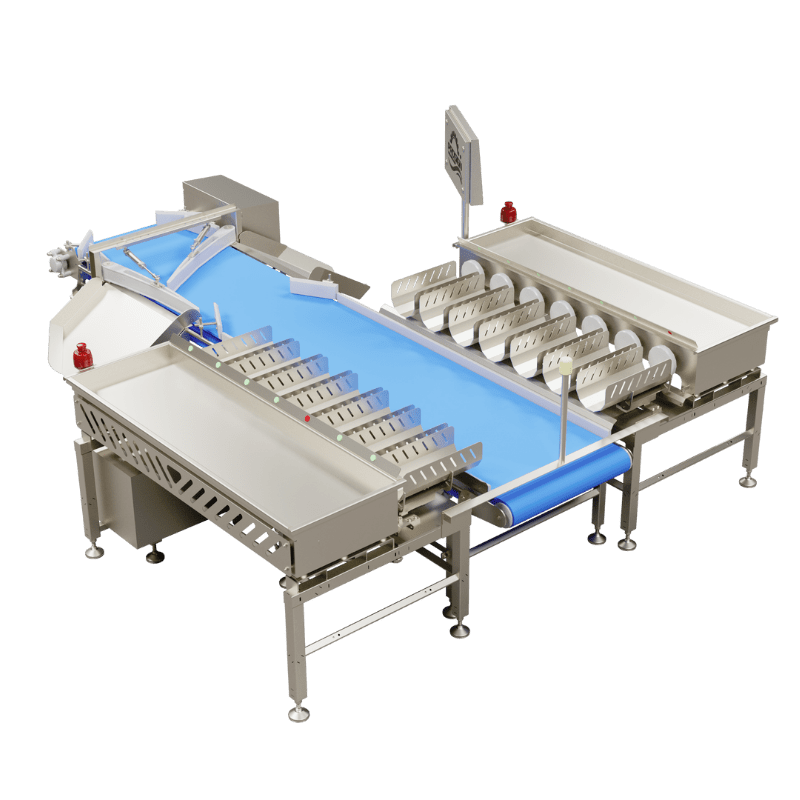

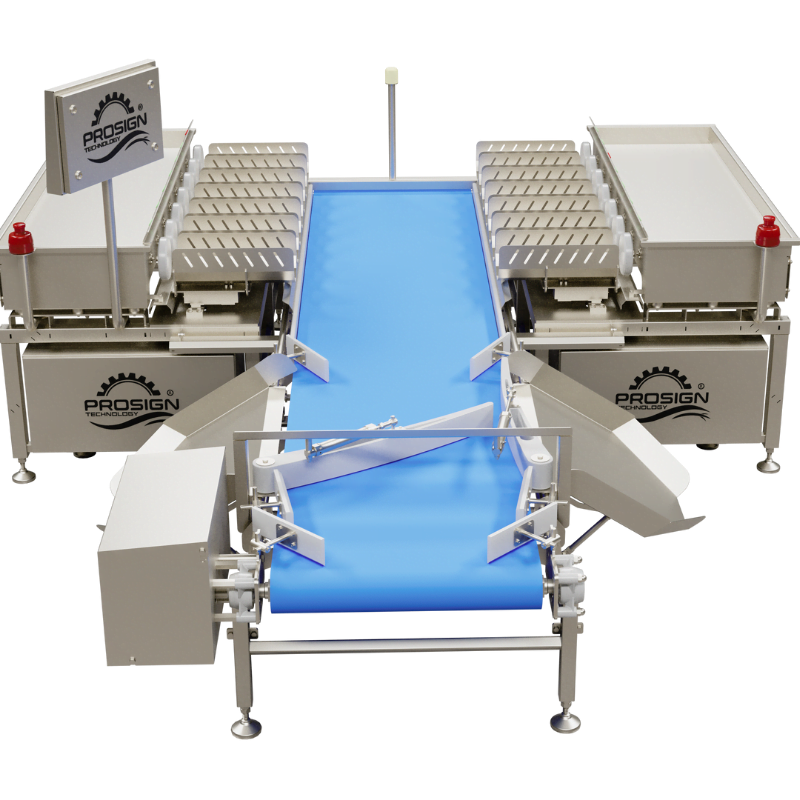

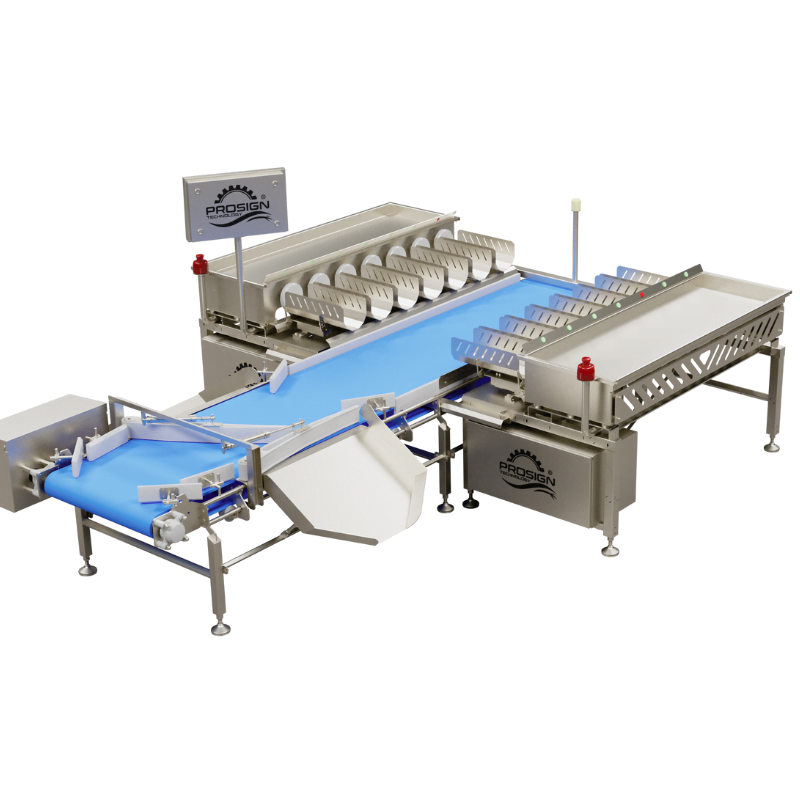

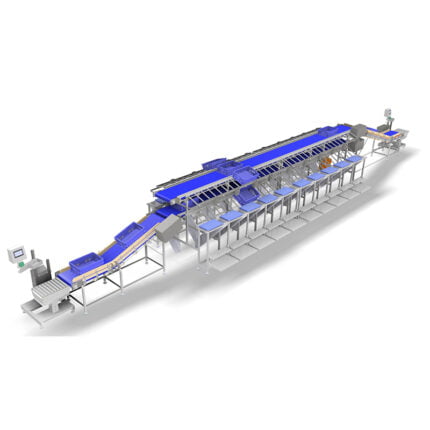

The products to be packaged are placed one by one in 14 pans with precision scales underneath in the feeding area with the help of personnel. After the products are weighed in these pans, they are poured into the product conveyor in boxer logic with the help of pneumatic cylinders behind the pans.

The feeding personnel can understand the availability of the pans with the red and green lights in front of the pans.

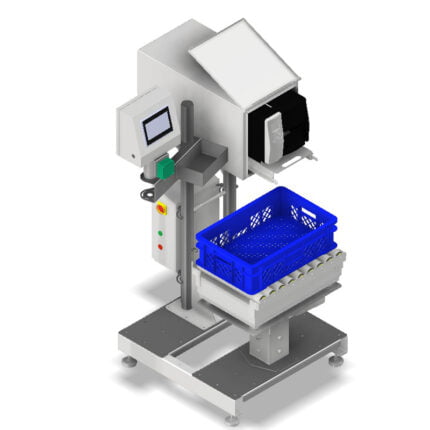

The accuracy of the batch formed as a result of the completion of the movement of the pans in kilograms can be observed from the tower lamp.

If the batch kilogram is off target or if there are products out of the batch; the products are removed from the right and left panson the conveyor out of the system.

Key Features

Suitable for fresh, frozen or fragile products

Overweight or underweight batches are automatically rejected for re-weighing

Compatible with Arde Studio production software, for a full overview of the packing process.

Red Meat Processing

Red Meat Processing Poultry Processing

Poultry Processing Sea Food Processing

Sea Food Processing Hygiene Equipment

Hygiene Equipment Other Sectors

Other Sectors Second Hand

Second Hand We Represent

We Represent Our Agents

Our Agents