Process Flow & Performance Features

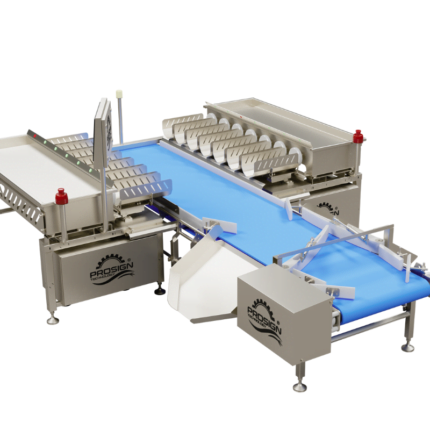

* Loading unit and slot feeding belt. After the ice separation process, the products are poured onto the feeding table with the Z conveyor to be sent to the feeding belt. Operators place the fish into the slots one by one, with the fish head in the direction of flow. The capacity of the whole system will depend on the capacity of these two operators.

* Acceleration and opening conveyors gradually accelerate the fish after slot feeding to create enough space between each fish for precise weighing as the product passes through the dynamic weighing unit.

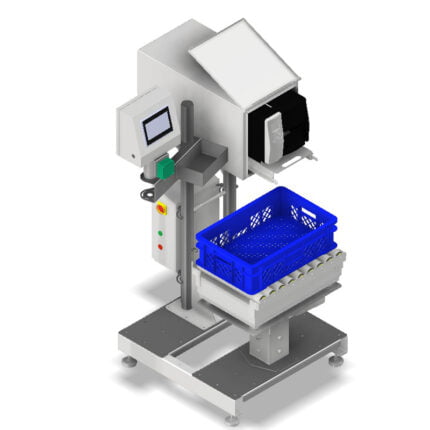

* The dynamic weighing unit weighs the fish and according to this weight, the product is assigned to the correct pan or door and then directed to the sorting section. The dynamic weighing unit can operate with a capacity of 55 – 60 products/minute when the correct feeding and conditions are provided. (Product sizes will affect capacity)

* Automatic closing pans are specially designed for salmon and similar large products, and there is a fish selection chamber and an angled crate placement area in the product receiving areas.

Red Meat Processing

Red Meat Processing Poultry Processing

Poultry Processing Sea Food Processing

Sea Food Processing Hygiene Equipment

Hygiene Equipment Other Sectors

Other Sectors Second Hand

Second Hand We Represent

We Represent Our Agents

Our Agents